ABOUT US / 關于我們

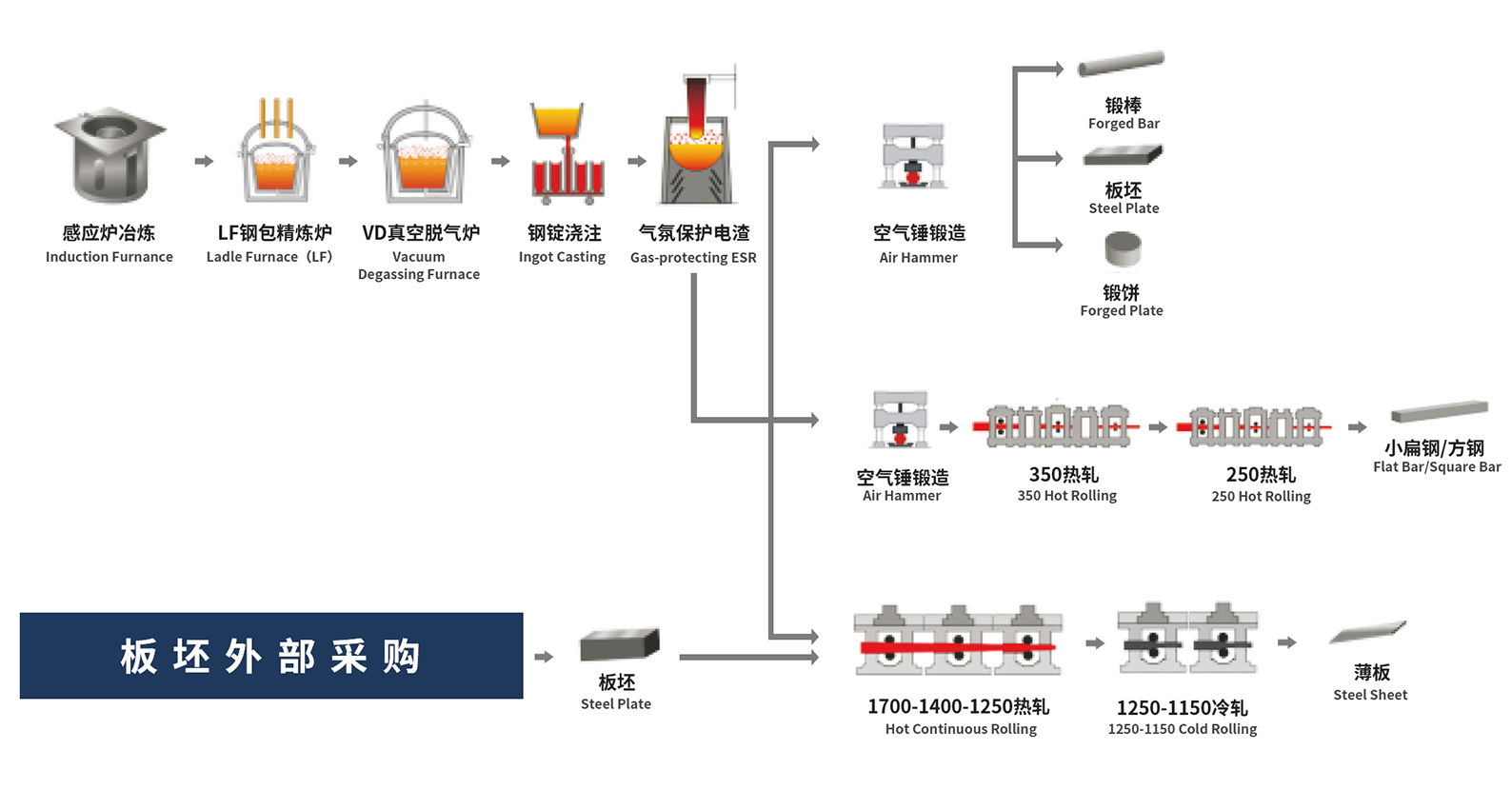

The company has a complete set of processes including smelting, Electro-slag remelting, forging, rolling, shearing, machining, heat treatment, surface treatment, etc. And it can further utilize returned materials and leftover materials. Zhejiang Sanfeng will gradually phase out its own smelting capacity in the future, purchase large state-owned enterprise slabs for back-end processing, and extend the industrial chain by deep processing products in the latter end。

1. 冶煉

Our high-quality molds undergo preliminary melting and alloy adjustment through an induction furnace to remove slag. The relatively small induction furnace type ensures greater flexibility in our process, allowing Sanfeng to smelt small batches, multiple varieties, and customized special steel grades for customers。

2. LF+VD爐外精煉

Through our subsequent external technical treatment, we can achieve a higher level of quality in our tooling materials。

We adopt LF+VD external refining process to effectively remove gas contents such as N and O in molten steel, improve purity, and adapt to increasingly complex market demands and domestic standards for high-quality tool and mold steel。

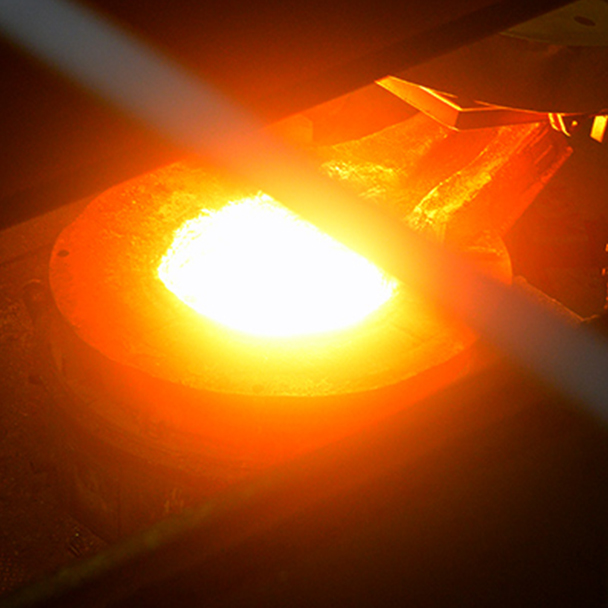

3. ESR電渣重熔

High quality electroslag ingots can be produced by our atmosphere protected Electro-slag remelting equipment. Improving the crystal structure of ingots; Reduce non-metallic impurities and inclusions in steel; Control the atmosphere inside the furnace to prevent an increase in H, N, and O content in the steel. Meet customer requirements for high purity materials。

4. 鍛造/軋制開坯

The Hot working of electroslag ingot is transformed into semi-finished slab suitable for rolling through forging/rolling blooming process; Alternatively, forging blanks of different specifications can be made as finished products for flat steel. Through our 8T air hammer or 1700 rolling mill, Ledeburite and banded carbide in high-speed steel ingots can be fully broken to obtain fine and dispersed structure. The carefully controlled annealing process ensures the optimal microstructure and machinability of the forging billet。

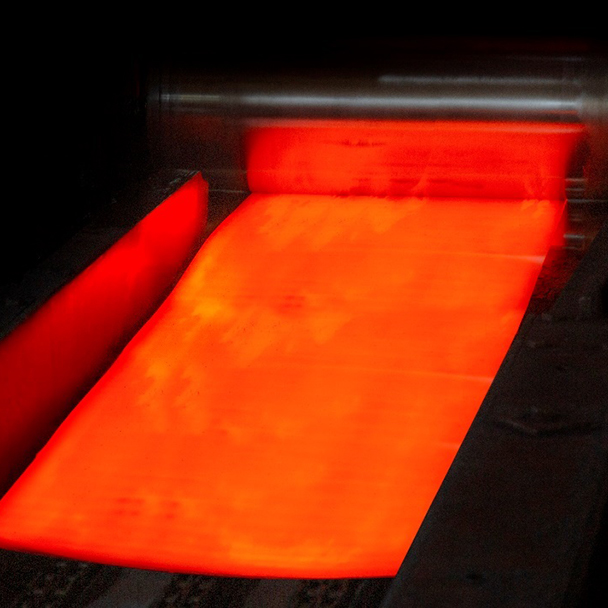

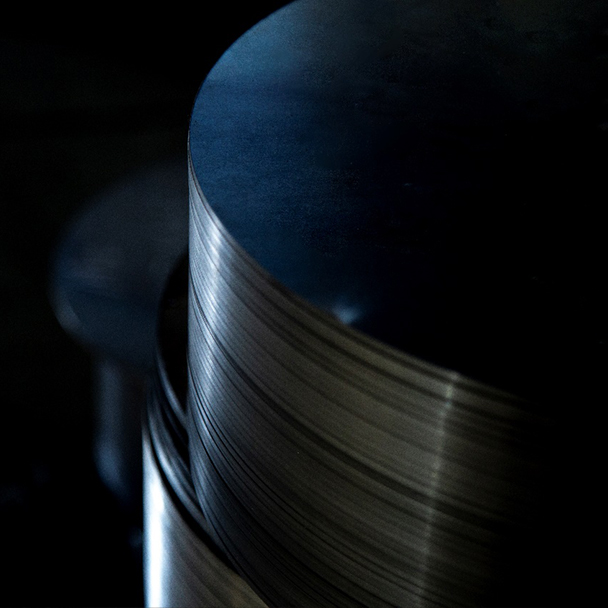

5. 軋制

Customized sizes of plates can be produced on the unique 1400-1250 hot rolling production line and cold rolling workshop of Sanfeng, and we pay special attention to customer requirements. To ensure high quality, all plates are produced by cross rolling. The boards in delivery status are all processed through our flattening process, vacuum annealing process, surface treatment process, etc. Use ultrasonic equipment to perform thickness tolerance checks on plates, as well as surface defect checks on each plate, to ensure the quality and supply stability of the factory produced plates。

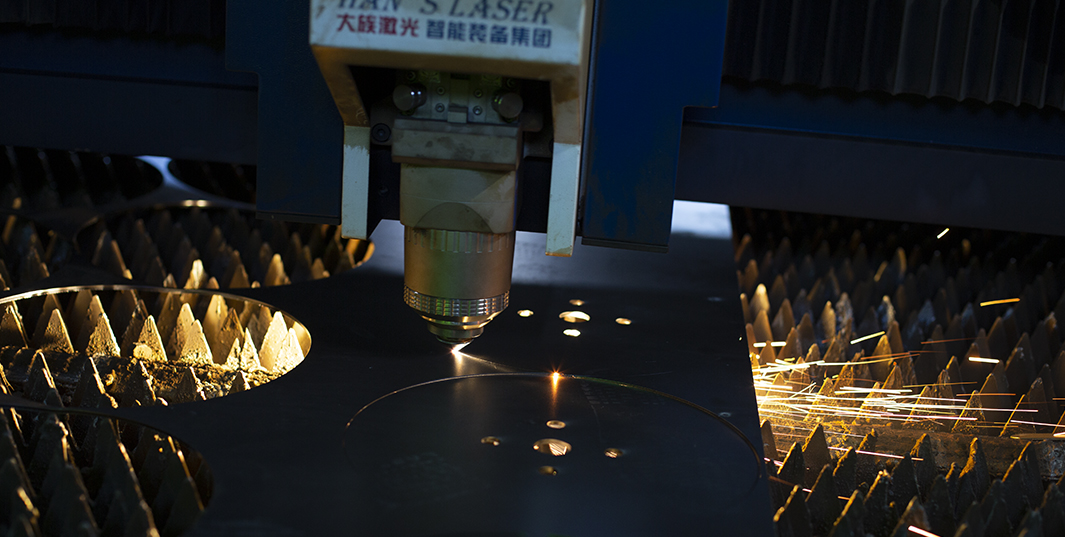

6. 機加工

Through subsequent machining processes such as straightening and finishing, laser cutting, stamping forming, grinding, milling, and CNC machining centers. We can obtain deep processing derivatives for plates and flat steel, such as circular saw blades, precision boards, planers, turning tools, etc. At the same time, it can meet customer customization needs and customize finished cutting tools according to drawing requirements。

7. 熱處理

In the Sanfeng factory area, we have an independent heat treatment workshop for pre hardening treatment of deep processed products. Obtaining the red hardness, hardness, strength, and wear resistance of high-speed steel materials through vacuum quenching and tempering treatment。

8. 質檢/倉儲

We have independent warehouses for semi-finished and finished products, using a modern steel WMS warehouse management system. Ensure that each batch of outbound products can undergo after-sales quality traceability。